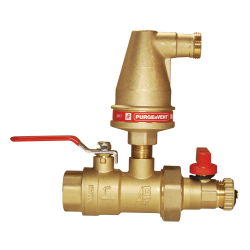

Automatic air vents help prevent corrosion

and are required by NFPA 13, 2016

and later editions.

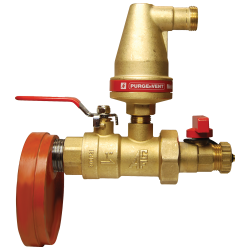

Automatic air vents help prevent corrosion

and are required by NFPA 13, 2016

and later editions.

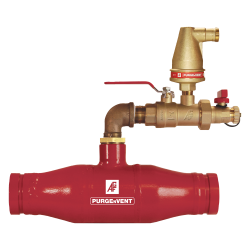

Automatic air vents help prevent corrosion

and are required by NFPA 13, 2016

and later editions.

View upcoming webinars

AGF University is able to offer continuing education credits for:

We are pleased to offer free webinars, on-demand training, and hands-on learning opportunities in conjunction with General Air Products at the Training Center in Exton, PA.

Please visit AGFU to see the upcoming session or to request training for your group

AGF University also offers recorded sessions that can be completed at your own pace.

Complete all of the AGFU on-demand courses and become a Certified AGF Product Expert.