Fire sprinkler system maintenance keeps a system ready that could save your life. Everyone hopes fire sprinklers never need to activate–that there’s never a fire. But the worst scenario for building tenants and property is a system that doesn’t work when they need it.

Maintenance doesn’t need to cause a headache for facilities professionals, though. With these five tips, building managers can maintain a safe fire sprinkler system with ease.

1. Test Your System Remotely

NFPA 13 and NFPA 25 both require sprinkler water flow alarm device testing. An inspector operates the test valve handle to simulate system activation.

NFPA 13 and NFPA 25 both require sprinkler water flow alarm device testing. An inspector operates the test valve handle to simulate system activation.

For facilities with multiple buildings or levels, testing is time-consuming. The inspector must visit each floor in person to test the valve. Plus, valves are often located behind locked doors or in hard-to-access places.

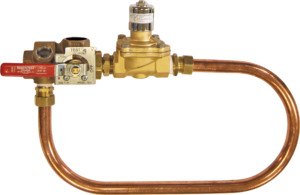

AGF Manufacturing’s RemoteTEST makes the process more efficient. It adds a solenoid to one of their famous TESTanDRAIN valves. Activate the solenoid with a local key switch, auxiliary panel, addressable FAC panel, or even a LAN system. Plus, manual testing is still an option if necessary.

How does that make testing easier?

Remote testing means you can test from one central location. Put a panel in each building that the inspector can use to test every floor. Or, have one hub from which the inspector can test every system on a large campus.

That not only increases efficiency, but it lowers the labor cost of testing. Cost and time savings encourage proper system maintenance and readiness.

2. Prevent Corrosion

The biggest threat to your system is one you can’t see from the outside–corrosion.

The biggest threat to your system is one you can’t see from the outside–corrosion.

Corrosion occurs when a ferrous metal or alloy reacts with water and oxygen. It’s irreversible and can cause the accelerated deterioration of the system.

Over time, corrosion can obstruct the flow of water through the sprinkler heads. Obstructions make the system ineffective. That increases the risk of injury and property damage in a fire.

It can also cause leaks that cost the facility thousands in damage.

Most of the oxygen that contributes to corrosion in a wet system is from trapped air. Studies conducted by the National Fire Protection Association (NFPA) show that venting trapped air could help prevent corrosion

Since the 2016 edition of NFPA 13, NFPA requires air vents on wet sprinkler systems. AGF’s PURGEnVENT Model 7900 automatic air vent releases trapped air automatically.

It’s the simplest form of fire sprinkler system maintenance. Install it once, and it will automatically vent trapped air to help prevent corrosion.

3. Monitor Corrosion

Catch corrosion early, and you have more time to handle it, or at least get an idea of the corrosion rate.

Catch corrosion early, and you have more time to handle it, or at least get an idea of the corrosion rate.

NFPA recognizes the importance of monitoring corrosion. In NFPA 13 – Chapter 23, they say a system shall use one of the listed options to monitor corrosion if the water supply has conditions contributing to microbiologically influenced corrosion.

One of those options is installing a corrosion monitoring station and monitoring it at established intervals.

AGF’s CORRinSITE is a simple corrosion monitor to fulfill this requirement. It requires no power and works for wet or dry fire sprinkler systems.

How does it work?

A plug made from the same material as the piping in the system is attached through a section of inline pipe or a mechanical tee. The plug has a chamber with a wear dimension of 0.040 inches. That’s 1/3 of the thickness of Schedule 10 pipe and 1/5 the thickness of Schedule 40 piping. When this corrodes through, moisture enters the chamber and turns a dot on its face from white to fluorescent orange.

CORRinSITE shows you when you have an internal corrosion problem. It also gives you a way to figure out the rate of corrosion.

For example, let’s say you install CORRinSITE in a new dry system with Schedule 10 pipe. The indicator turns orange five years later. That shows building managers that 1/3 of the pipe corroded in five years. So, they can know the system will likely need replacement in ten more years. Now, they have time to budget and prepare before corrosion becomes a major issue.

4. Protect Against Freezing

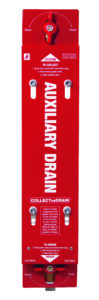

Dry sprinkler systems, although they are not full of water, still collect condensation. NFPA 13 requires auxiliary drains to collect and drain that moisture. Their design allows them to do that without tripping the system.

Dry sprinkler systems, although they are not full of water, still collect condensation. NFPA 13 requires auxiliary drains to collect and drain that moisture. Their design allows them to do that without tripping the system.

Frozen Auxiliary Drains Cause Flooding

In freezing temperatures, water left in the drain can freeze inside the barrel. When frozen water partially thaws and refreezes, it can break the drain. Ice plugs form that force new ice expansion downward, breaking the valve.

When the ice thaws, a broken valve means pressure loss and a tripped system. A tripped system with a broken drain means facility flooding that causes:

-

-

- Expensive property damage

- Safety hazard

- Inconvenience to building tenants

- Slip and fall liability

-

Those issues are expensive to resolve. Repairing the fire sprinkler system alone will cost. It requires labor to fix the broken valve and drain the system. Plus, someone must return daily to drain residual moisture to prevent another freeze.

Freeze Protection

AGF offers water detectors for the COLLECTanDRAIN auxiliary drains to prevent freezing. The detector creates visual and auditory alerts when the drain needs maintenance. Plus, signage adhered to the drain explains operation for less experienced personnel.

For more problematic auxiliary drains, AGF offers a heated cabinet. It prevents the water from freezing and alerts when it’s in need of draining. Plus, some models offer automatic draining.

5. Protect Against Vandalism

Parking structures, garden centers, and stadiums all may need dry systems. So, the public often has access to auxiliary drains. Public access and convenient drain handles lead to accidental and malicious vandalism.

Parking structures, garden centers, and stadiums all may need dry systems. So, the public often has access to auxiliary drains. Public access and convenient drain handles lead to accidental and malicious vandalism.

Anti-trip plates prevent misuse of an auxiliary drain. AGF manufactures an anti-trip plate on their Model 5100 and 5200. It makes it impossible to improperly operate the valve. For added security, a locking kit is available that requires a key to operate the valves.

Fire Sprinkler System Maintenance Keeps You Protected

It’s vital to keep a building’s fire sprinkler system in top shape should a fire start. But busy facility managers may not have fire sprinkler maintenance top of mind. Issues like inefficient testing, corrosion, freezing, and vandalism may fall through the cracks. They’ll go unnoticed until they cause massive safety and financial costs.

With innovative, efficient, and code-compliant products from AGF, maintenance is easier. And easy maintenance means a system in top shape and people and property protected.

A version of this article was printed in the September 2019 issue of Building Services Management magazine.