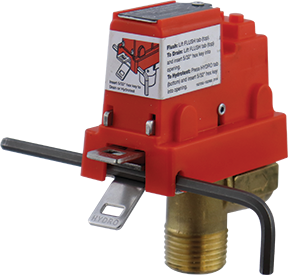

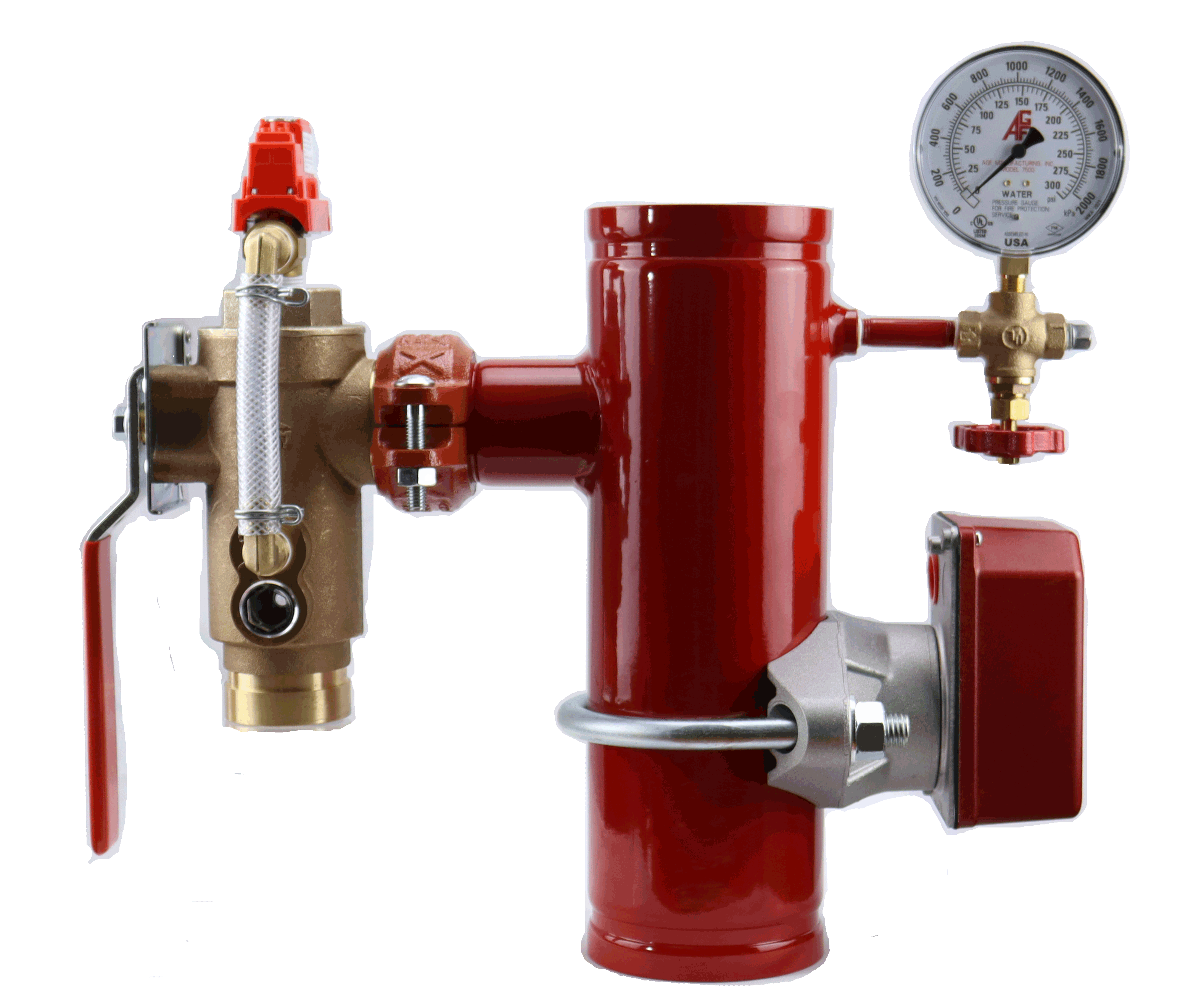

AGF’s Model 5900 Flood Eliminator flood preventer device won a 2021 Maintenance Innovation Award from Facility Maintenance Decisions. The Flood Eliminator prevents flooding in facilities due to broken fire sprinkler auxiliary drains.

AGF’s Model 5900 Flood Eliminator flood preventer device won a 2021 Maintenance Innovation Award from Facility Maintenance Decisions. The Flood Eliminator prevents flooding in facilities due to broken fire sprinkler auxiliary drains.

Continue reading Flood Preventer Device Wins Maintenance Innovation Award →