Fire sprinkler system freeze prevention is vital for facility managers as temperatures drop. Compromised life safety, facility damage, and more plague facilities with poor maintenance plans.

Proper auxiliary drain maintenance is key to preventing freezing on dry sprinkler systems. Facilities can save thousands each winter with these key steps:

-

-

- Locate Auxiliary Drains

- Perform Preventative Maintenance

- Use Correct Service Frequency

- Simplify the Plan

-

So how do you maintain auxiliary drains, and what are they? Let’s dive in.

What is a Dry Fire Sprinkler System?

Dry fire sprinkler systems protect areas that cannot remain over 40 degrees Fahrenheit. These include parking garages, stadiums, outdoor walkways, storage facilities, loading docks, and more.

Despite the name “dry,” condensation forms in the sprinkler pipes of these systems. By design, it accumulates in assemblies known as auxiliary drains, low-point drains, or drum drips.

Emptying accumulated water from auxiliary drains is a vital part of fall and winter maintenance. Cold temperatures can freeze and expand the water, which can break the auxiliary drain.

A broken drain releases the air pressure in the dry system and activates it. That causes flooding, property damage, and an unprotected facility while the system is being repaired.

Fire sprinkler system freeze prevention includes a simple and consistent maintenance plan. All it requires is locating all the facility’s auxiliary drains and keeping them empty.

Step One: Locating Auxiliary Drains

What do auxiliary drains look like, and where can facilities personnel find them? This is where code requirements come in.

What do Auxiliary Drains Look Like?

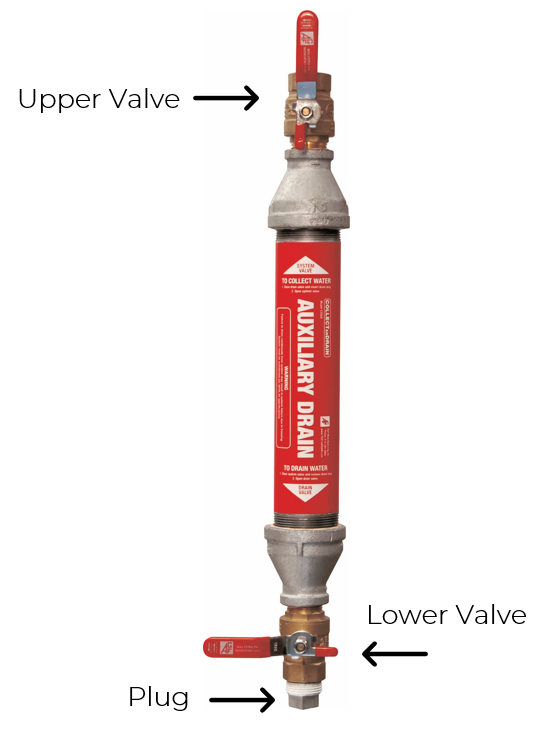

NFPA 13: Standard for the Installation of Sprinkler Systems describes an auxiliary drain as two 1” valves, a 2” by 12” condensate nipple, and a plug or cap. Essentially, this looks like a piece of pipe with valves that have handles on either end.

Code also requires labels on auxiliary drains. So, there should be a hanging sign or identifying marker that says, “auxiliary drain.”

The exact look may vary from system to system. Some systems use consistent, pre-assembled drains. Others use extra components assembled in the field. Some installers leave a plug or cap on the bottom, while others attach a drain line.

Where are Auxiliary Drains?

Locating every auxiliary drain can be more difficult than identifying them. The number of drains on a system varies, and a single drain missed can cause a break.

Auxiliary drains are part of dry or preaction systems. As mentioned before, these protect areas with temperatures below 40 degrees. Look in areas like loading docks, garden centers, or parking garages.

Code requires drains to be accessible. So, there should be no barriers to prevent service.

Code also requires a sign or map listing the number and locations of all auxiliary drains in the system. But, many industry professionals are unaware of this need.

If a facility has this sign, it’s near the dry valve. Dry valves should be in a heated room or enclosure with other system equipment.

If your system doesn’t have this sign, ask the system installer or attempt to locate all the drains yourself.

To help locate drains, some manufacturers offer water detector devices. Install these devices on each drain. They send visual and/or audio alerts and remote notifications when a drain needs service. That makes it much easier for personnel to find drains needing attention.

Step Two: Performing Drain Maintenance

Once personnel locate a drain, how should they perform maintenance? This process is simple, but pay careful attention to the order of the steps.

The upper and lower valves on the drain should never be open at the same time. Having both open compromises system pressure and activates the system as if it was tripped.

How to Empty an Auxiliary Drain:

-

-

- Close the upper valve.

- If there is one, remove the plug or cap at the bottom of the drain.

- Open the lower valve.

NOTE: Unless attached to a drain line, have a bucket ready to catch drainage. - Allow any accumulated water to drain.

- Close the lower valve, open the upper valve, and allow for more water to accumulate.

- Repeat step 5 until no more water drains from the valve.

- Close the lower valve and replace the plug or cap (if there is one).

- Open the upper valve.

- Close the upper valve.

-

-

- Always end with the lower valve closed and the upper valve opened. That allows for the proper accumulation of more condensation.

Step Three: Service Frequency

How Often Should You Service Auxiliary Drains?

NFPA 25: Standard for the Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems provides requirements on how often to service drains. It requires service after system operation and in preparation for cold weather.

After the system operates and is reset, there will be residual traces of water left in the pipes to drain. When preparing for cold weather, water removal prevents freezing.

In both circumstances, code requires emptying drains daily to start. Then, the frequency could change if several days in a row show no water accumulation. Lengthen to once every few days or once every week, for example.

But, when temperatures fluctuate above and below freezing, daily may be the best option. Those temperature fluctuations are the biggest cause of broken auxiliary drains. The water thaws and re-freezes unevenly and puts pressure on the components.

Step Four: Simplifying the Plan

Emptying an auxiliary drain is simple, but the rest of the process has potential for human error. Accessories on the market, like the water detector mentioned above, simplify the plan.

Flood elimination devices are a fail-safe to prevent a flood should the drain break. They detect a sudden rush of pressurized water and restrict the flow to the drain. That eliminates the flooding that would occur with an unprotected break.

Heated cabinets installed alongside traditional auxiliary drains at a university.

Heated cabinets installed alongside traditional auxiliary drains at a university.

Heated cabinets encase the drains in a temperature-controlled environment. That provides more flexibility in draining schedules. An energy-efficient heater prevents the drain from freezing, so daily draining is unnecessary. Self-maintaining and automatic options also decrease the need for manual service.

Heat trace wiring is also an option. It’s typically used to protect small sections of wet pipe systems from freezing if they need to traverse unconditioned areas. It can also be used on dry systems. But, it’s the most expensive option to install, maintain, and operate on an entire system or many auxiliary drains.

Fire Sprinkler System Freeze Prevention Saves Money

Proper auxiliary drain maintenance is key for fire sprinkler system freeze protection. It keeps facilities’ systems in good working order to best protect lives and property. Plus, it saves thousands in facility damage by preventing freezing and flooding. With this guide, facility managers can create a solid plan for prevention in their facility this winter.

To purchase AGF’s auxiliary drains and accessories, find a distributor who serves your area.

A version of this article originally ran in the February 2022 edition of PUPN Magazine.